02 Sep 2022

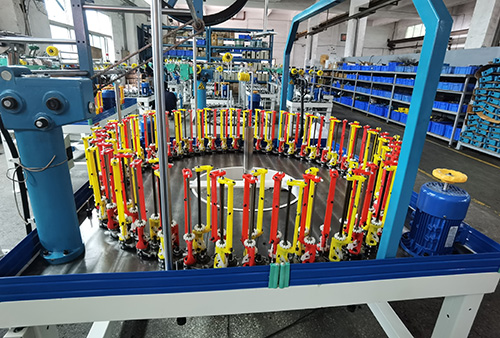

Concerning the HRD-BR-08 braiding machine, the spindle is driven by the spindle belt. Spinning frame application spindles with cotton webbing, rubber belts. The cotton spindle belt has long elongation, short service life and low price; the rubber spindle belt has stable transmission, low vibration, low noise, energy saving and long service life, but the price is more expensive. In the long run, it is a development trend that rubber spindle belts replace cotton spindle belts, which is worthy of promotion.

When the spindle belt joint is sewn (or glued), the spindle belt reel frame is installed and the transmission part is adjusted, it should be done:

The joint of the spindle belt should be straight, soft and reliable; the fixed length of the spindle belt should be the same. The width of the ingot belt is recommended to be 9-10mm. The spindle belt joint should be straight, soft and reliable, the joint length should be 40mm, the joint direction should be the same as the rotation direction of the spindle, and twisting of the twist is not allowed. Before bonding, the rubber ingot tape must be ground into a certain length of inclined surface (or the two ends are bonded), positioned on the hot pressing tool (the upper and lower grinding faces are coincident and fixed), and then the grinding surface Apply a thin layer of special adhesive, wait for a while to make it level and overlap, and then fix the two sides after hot pressing glue.

The tension of the spindle belt should be suitable

After adjusting the scale of the weight of the ingot reel to be consistent and the angle of the ingot reel according to the process requirements, the appropriate tension of the ingot belt should be about 8N, and a spring scale can be used to hook the ingot belt (the middle part of the two spindles) and pull it straight for the test. If the tension is too large, it will increase the radial load of the bearing on the spindle, aggravate the wear and affect the service life of the spindle; if the tension is too small, it is easy to stall, resulting in a large difference in spindle speed and high yarn unevenness.

The working position of the spindle belt should be normal

Whether the working position of the spindle belt is normal or not is very important to the spindle transmission. Do a good job in the positioning of the height, front and rear, left and right positions of the ingot belt reel. High and low position: When the ingot tape reel is in a vertical position, the top surface of the ingot tape reel should be on the same horizontal plane as the centerline of the arc groove of the spindle rod. If the horizontal position of the spindle belt is too high or too low, the spindle belt will not be centered. It sinks and rubs the underside of the spindle rod, which causes the spindle belt to impact the spindle and vibrates, and also causes the underside of the spindle belt to wear out prematurely; floats up, causing the spindle to jump up and pull the upper edge of the spindle belt and damage it, which not only affects the quality of the finished yarn, but also increases the end breakage. It also causes abnormal wear of the lower cone part of the spindle, resulting in damage to the spindle, which is extremely harmful. Front and rear position: The ingot belt reel should not touch any parts after it is pushed forward and backward, and there should be a gap of not less than 13mm. The front and rear swings are naturally flexible and not tightly rolled, and the swing angle is basically the same. You can adjust the neck of the ingot belt reel shaft. The angle of the circle is corrected. Left and right position: The spindle belt should not rub against the spindle tape reel bracket or the side surface of the spindle tape reel during the transmission process. The surface of the spindle belt should not adhere to flying flowers or oil. In order to make the surrounding arc of the spindle belt to the four spindles as close as possible to reduce uneven twist, the position of the spindle belt reel should be as far as possible to the left (keep 6- -8mm clearance), on the principle of not touching the spindle belt when driving. The whole trolley should not have the phenomenon of "dead spindle belt".

In short, when adjusting the work of the spindle belt and the spindle transmission part, we must pay great attention to be careful and careful operation, and we can't just pay attention to the improper practice of the spindle belt driving the spindle on the spindle belt reel.

Keywords: braiding machine

Originally published 02 Sep 2022, updated 02 Sep 2022.