06 Jan 2024

In the intricate world of textile production, where precision and quality are paramount, sample warping machines stand as essential instruments in the early stages of the manufacturing process. Among the array of features that define the excellence of these machines, the intermingle function takes center stage. This article delves into the significance and multifaceted role of the intermingle function in sample warping machines, exploring its impact on yarn quality and the broader landscape of textile innovation.

The Essence of Intermingle in Sample Warping Machines

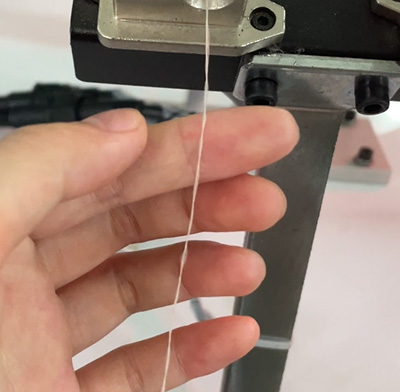

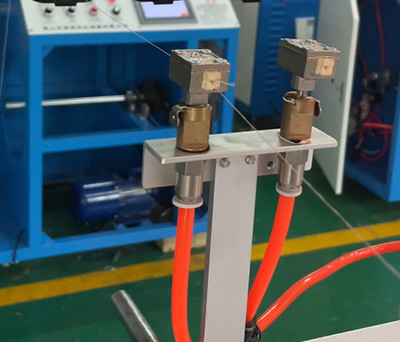

Intermingle, in the context of sample warping machines, is a specialized function designed to introduce controlled intertwining of individual yarn filaments within a bundle. This deliberate interlacing serves as a transformative step in shaping the yarn, enhancing its structural integrity, and influencing the characteristics of the final textile product. While traditional warping focuses on creating yarn for subsequent production, the intermingle function in sample warping machines introduces an additional layer of experimentation and customization.

Key Features of Intermingle Functionality

Precision Control: At the core of intermingle functionality is its ability to exercise precision control over the intertwining process. This ensures that the intermingle function enhances yarn cohesion without compromising the essential attributes of individual filaments.

Adjustable Density Settings: Sample warping machines equipped with intermingle functionality often come with adjustable settings for intermingle density. This adaptability allows manufacturers to experiment with different levels of intertwining, catering to the diverse requirements of various textile applications.

Keywords: sample warping machine

Originally published 06 Jan 2024, updated 06 Jan 2024.