26 Jan 2024

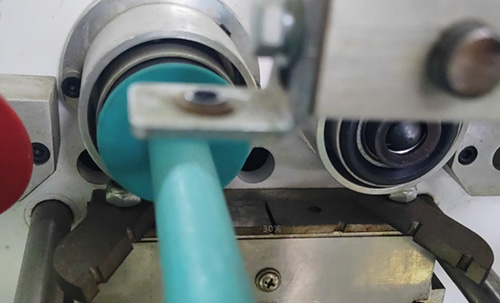

The scissor cutter represents a fundamental yet highly efficient tool within winding machines, tasked with the precise cutting of yarn as it is wound onto spools or bobbins. Unlike other cutting mechanisms, the scissor cutter operates with a traditional yet effective design, providing a straightforward and reliable solution for achieving clean and accurate cuts.

As introduced in before article, yarn winding machine has another cutting way called heater cutter. But heater cutter has its limits, cannot use for cotton fiber and glass fiber. Because cotton fiber is inflammable easy burned, and glass fiber is too strong. Then these specialty fibers yarn need to use scissor cutter.

Key Features of the Scissor Cutter

Mechanical Simplicity: The scissor cutter boasts a straightforward and mechanically simple design, relying on the traditional scissor mechanism. This simplicity enhances reliability and ease of maintenance, ensuring consistent performance in yarn cutting.

Precise Cutting Action: The scissor cutter's design facilitates precise cutting action, ensuring that each cut is clean and accurate. This is crucial for maintaining the integrity of the yarn during the winding process, contributing to the production of high-quality yarn packages.

Adaptability to Yarn Types: One of the notable advantages of the scissor cutter is its adaptability to various yarn types. Whether handling natural fibers, synthetic materials, or specialty yarns, the scissor cutter proves versatile, making it a dependable choice for diverse textile manufacturing applications.

Reduced Friction and Tension: The scissor cutter minimizes friction during the cutting process, reducing tension in the yarn. This contributes to cleaner cuts and helps preserve the structural.

Keywords: yarn winding machine

Originally published 26 Jan 2024, updated 26 Jan 2024.