16 Dec 2022

According to the number and length required by the weaving or knitting process, the yarn is evenly warped onto the beam with a certain tension for use by the needle loom. This process is called warping. The yarn warping machine and the needle loom are inseparable, the quality of the warping has a great influence on the weaving production. Practice has proved that about 70% of the defects in the weaving and knitting are caused by poor warping. It can be seen that a good yarn warping machine is very important.

As its name implies, the sample yarn warping machine is suitable for sample orders or small orders. When the factory receives new customer orders or new products, it needs to confirm the sample before mass production. The sample warping machine warps the yarn onto the beam according to the actual consumption, and then put the beam on the needle loom to make samples without wasting materials.

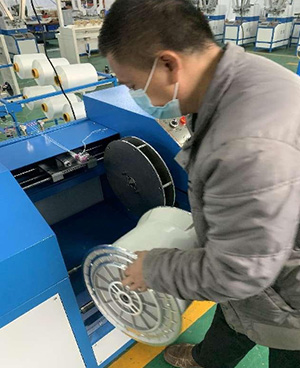

Our warping machine has three models, HRD-838, HRD-848 and HRD-858. Among them, HRD-838 and HRD848 beams are common, outer diameter 300mm and height 295mm. The beam of HRD-838 maximum number of yarn is 100 ends, and the yarn total weight can reach to 2KGS. And the beam of HRD-848 maximum number of yarn is 200 ends, and the yarn total weight can reach to 2.5KGS. The HRD-858 beam outer diameter 365mm and height 305mm, the maximum number of yarn is 200 ends, and the total yarn weight can reach to 4.5KGS. HRD-858 warping machine and beam are available to be customized.

The beams are different between sample yarn warping machine and mass production yarn warping machine. The inner diameter of the sample warping beam is larger, beveled edge design make sure the yarn won’t be pressed while weaving process, and the beam can be used for more than 10 years under normal use.

Keywords: yarn warping machine

Originally published 16 Dec 2022, updated 16 Dec 2022.