11 Nov 2022

Although the yarn winder is only a textile auxiliary equipment, it is important. Yarn winders are required for many textile jobs. Its function is to distribute the large yarn rolls to the bobbins according to the requirements, so that the yarn bobbins can be used together high-speed braiding machines to make shoe lace,lace etc.

There are hundreds of yarn winder on the market, including manual, semi-automatic and fully automatic. The quality varies, and the price varies also. We suggest that users choose the machines according to their actual needs, which is not expensive but suitable. Traditional family workshops do not have high requirements for efficiency, manual yarn winder can meet production needs. Small and medium-sized factories have requirements for quality and efficiency, so semi-automatic or fully automatic yarn winder are more suitable for them.

The yard counting function ensures the uniform length of yarn winding on the bobbins, one-time yarn change on braiding machine, reduces downtime, increases the output by 30%, reduces the waste of yarn, and saves staff workload. The ordinary yarn winder has the function of counting number of coils only. What is the difference between counting number of coils and yard counting? The counting number of coils is to wind the yarn according to the setting. Although each bobbin has the same number of coils, due to the different pressure on the yarn while winding, the tightness of the yarn on the bobbin is different, the number of coils are same but different length.

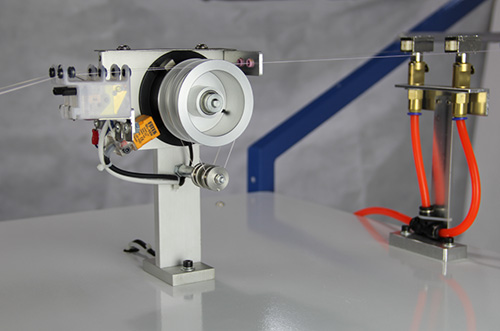

As its name implies, yard counting is calculating length, 1 yard is equal to 0.9144 meters, the yard counting function makes the yarn length on each bobbin consistent, and the maximum tolerance is two thousandths only. Regardless of the size of the yard counting device of yarn winder, it contains advanced technology and precise design. The yard counting wheel is made of aviation aluminum and has electronic infrared sensor.

Before the yarn winder machine works, the yarn is passed through the hole in the creel, through the yarn presser, and then wound around the yard counting wheel, wind around the bobbin finally. When the yarn winder starts, the yarn drives the yard counting wheel with the rotation of the bobbin. After the yard counting wheel rotates one circle, the PLC system will receive the signal from the yard counter automatically.

Due to the different pressing force, the winding speed of the left and right bobbins is also different. When the bobbin on one side completes the work, the yard counter device transmits the data to the PLC system of yarn winder, and the system issues an instruction to wait for the bobbin on the other side to complete the work. Once the yarn length is same on both sides of bobbins, the yarn is cut and reloaded.

All the yard counting devices are tested before being installed on the yarn winder. After installing to the yarn winder, then run the overall test.

Keywords: yarn winder

Originally published 11 Nov 2022, updated 11 Nov 2022.