25 Nov 2022

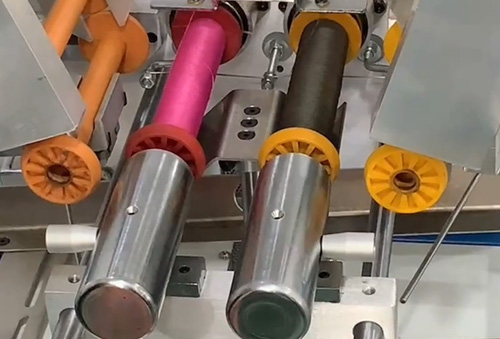

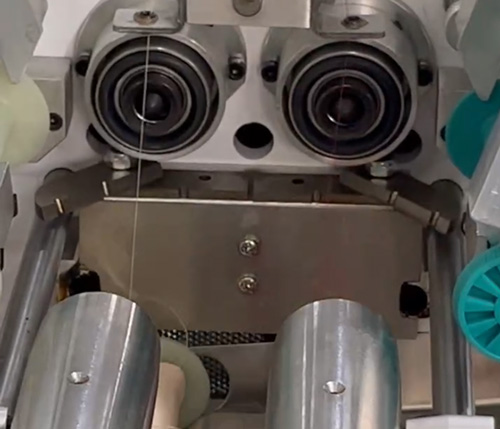

After the yarn winding machine completes the winding work, the outermost yarn between the bobbin and machine needs to be cut, and the bobbin can roll to the chute or fall to the designated position. Generally, there are two methods of cutting yarn, wire hot cutting and cold cutting.

What is the difference between wire hot cutting and cold cutting? First of all, we need to know what is wire hot cutting and what is cold cutting. Wire hot cutting is to heat the wire by electricity, and once the wire reaches the specified temperature, the yarn can be cut. The temperature and heating time of the metal wire on the winding machine can be adjusted and controlled by the PLC system. Wire heat cutting suitable for synthetic yarns, polyester yarns, nylon yarns, etc.

Cold cutting is to cut the yarn with scissor. Some yarns cannot be heated due to material reasons, such as cotton yarn, jute yarn which will burn when exposed to spark or fire. And there are some yarns materials too hard to be broken, need cold cutting also, such as metal yarn and fiberglass yarn.The scissors on our winding machines are made of high-quality alloy steel, which has a long life under normal use. In order to save costs, some factories use scissors made of ordinary materials, which causes the scissors to wear out after a period of working time. When the scissors are worn out, they can only be replaced with new ones, which increases the workload and labor costs in the long run.

The quality of the machine directly affects the production efficiency. A high-quality equipment can be used for more than 10 years under normal conditions, while the service life of poor-quality equipment is only 2-3 years, and the failures are frequent. Therefore, when manufacturers choose equipment, they should not only look at the price. The main components of Rongju winding machines are from Taiwan. All the yarn winding machines with precisely yard counting or number of coils code counting function, sensitive yarn breakage protection device, and high-speed winding work. It is a good choice for the textile production industry.

Keywords: yarn winding machine

Originally published 25 Nov 2022, updated 25 Nov 2022.