04 Nov 2022

The production of ropes such as shoelaces requires yarn, but the raw yarn roll is too large for the braiding machine, the yarn needs to be split from the large raw yarn roll, and the role of the yarn winding machine is to wind the yarn to the bobbins, and during the winding process, the individual fibers are usually twisted together to form a twisted yarn to increase the thickness and strength. The ropes quality depends on the yarn, the material is the key factor.

There are a wide variety of yarns, colorful and dazzling, which makes the textile industry changeable. With the continuous development of the industry and the continuous improvement of production capacity, consumers have higher and higher requirements for commodities. How can manufacturers ensure product quality? Cleanliness is one of the most important factors in ensuring quality. Smart yarn winding machines can solve the problems.

For dark yarns, such as black, no need to worry too much about its neatness. But for Light-colored yarns, such as white, or colorful yarns are susceptible to contamination, special attention should be paid to maintaining cleanliness during production.

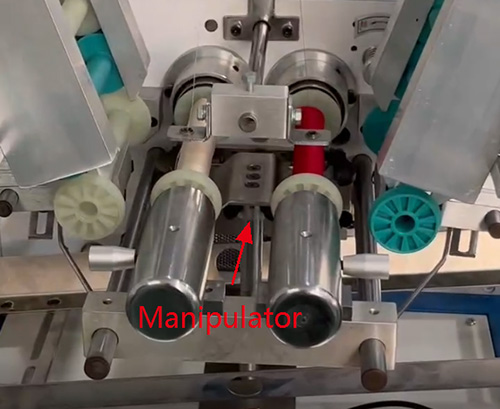

Our HRD-819, HRD-829 series yarn winding machine solves the trouble of being dirty. The newly developed automatic yarn feeding function, when the winding process is completed, the manipulator will lift up to catch the bobbins automatically, and then put the bobbins neatly on the chute to prevent falling to the ground or getting dirty.

HRD-829 yarn winding machine is equipped with an infrared sensor. When the number of bobbins on the chute reaches the maximum, the infrared sensor device will send out alarm signal, then the winding machine will stop working, and the alarm light will flash, the staffs will remove the finish bobbins after noticing the alarm light, to avoid bobbins buildup.

Both HRD-819 and HRD-829 yarn winding machine with upgraded automatic feeding function. HRD-819 with one layer of chute, HRD-829 with two layers of chute, which increases the space for placing bobbins. This improving production efficiency, and is suitable for manufacturers with high production capacity requirements.

Keywords: yarn winding machine

Originally published 04 Nov 2022, updated 04 Nov 2022.