13 Aug 2025

There are four steps to operating the automatic copper wire winding machine: Adding bobbins and clips; Threading wires; Inserting the power plug; Setting parameters and Starting the machine.

Supply

Electricity

Tools

Copper wires, Clips, Bobbin

Method

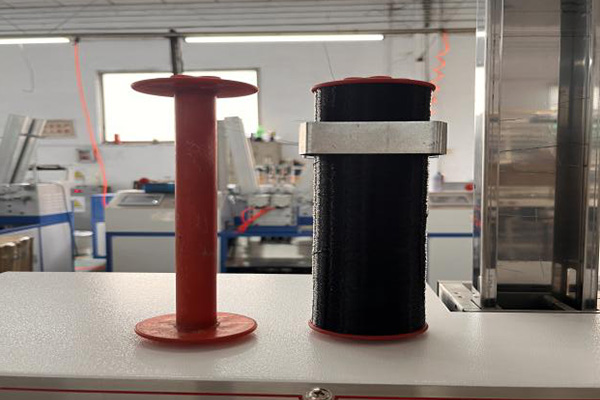

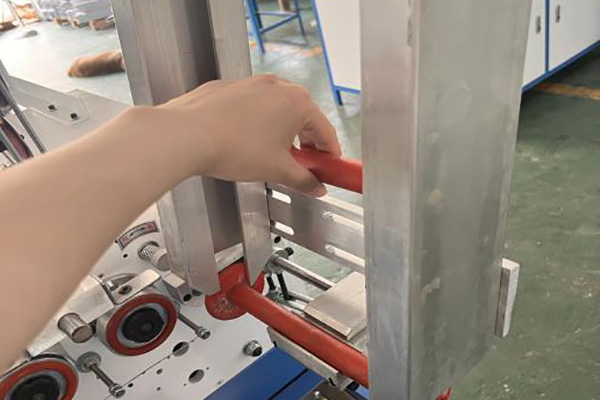

1. Place the bobbins and insert the clips into the chute.

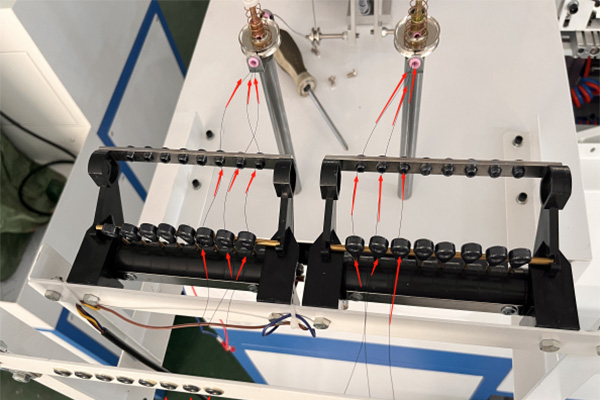

2. The copper wire winding process is performed as shown in the distributed operations pictures below. The copper wire sequentially passes through the ceramic eyelet on the creel, the yarn broken device, and the yarn presser, before finally entering the yarn combiner of the machine. This process combines three separate copper wires into a single strand, which is then wound onto the bobbin.

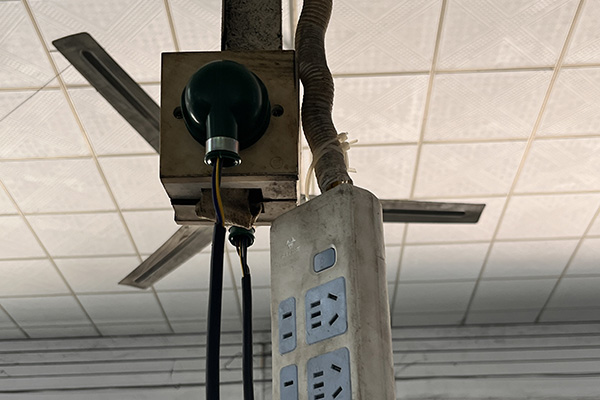

3. Inserting the power plug and turn on the power switch.

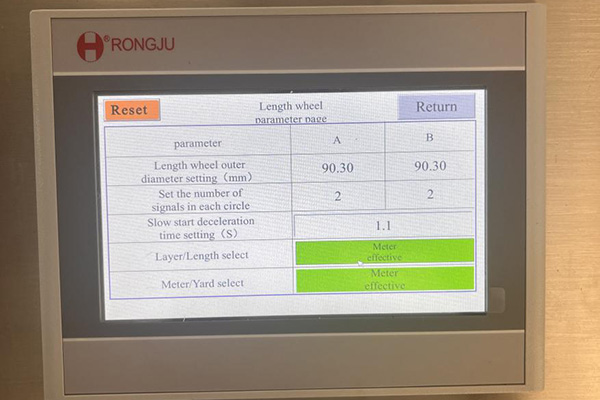

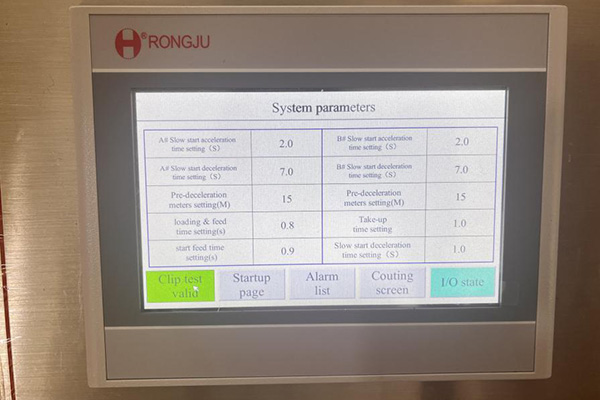

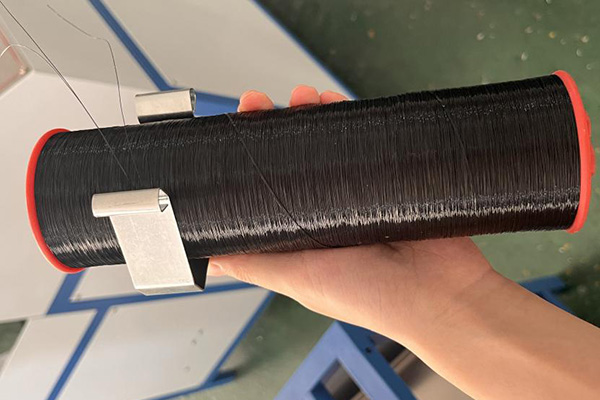

4. Firstly, set the "Meter effective". Secondly, set the "Clip test valid" to ensure the sensor activates when a chute is empty. This enable the touch screen alert "Clip used up, please check!" to prompt operators to add clips. Finally, press the "Run" button to start the machine. The finished product is shown in the following image.

Keywords: automatic copper wire winding machine

Originally published 13 Aug 2025, updated 13 Aug 2025.