07 Feb 2023

Automatic bobbin winder just winding the yarn from big cone onto the bobbin,the winding bobbin will be put onto high-speed braiding machine,the braiding machine just produce shoelace and shoestring.

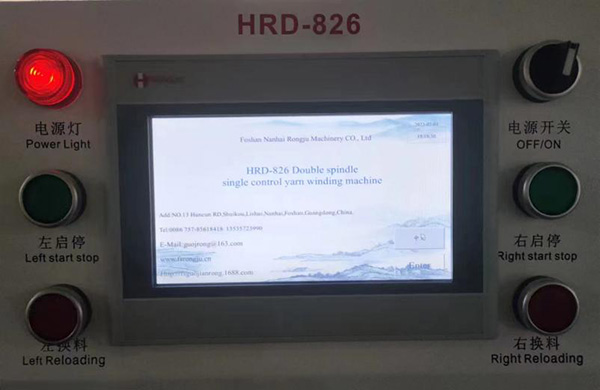

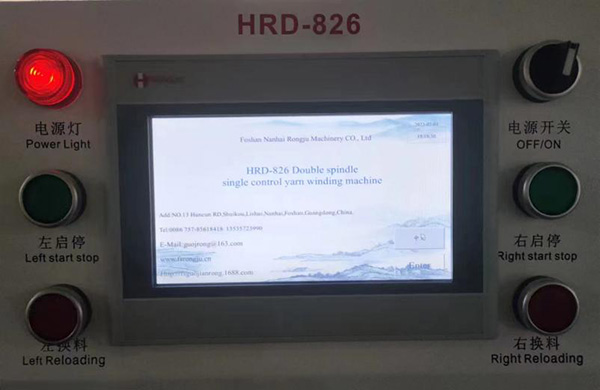

The touch screen is precision and sophisticate connected to electric board which installed inside machine. The electric board controls touch screen by advanced and complex PLC program.

Why need touch screen on bobbin automatic winder?

1. We can set production length,usually it is called yard,that means,when the winding completed winding the set certain length,the cutter will cut the yarn automatically,then bobbin feeder send another bobbin to continue winding.Step by step,bobbin by bobbin,winding automatically,neatly,accurately.

2. We can set speed data,include traverse speed and major speed on it,so the winding the yarn orderly,neatly,automatically at the set speed,will not affect the winding procedure and will not break the yarn due to different speed.

3. We can set cutter temperature,i.e. higher or lower the cut temperature according to different material and thickness of yarn. E.g. thin and normal yarn only need lower temperature,thick and special yarn need high temperature,to cut the yarn automatically,smoothly and quickly.

On the touch sreen,we set different languages:

1. Chinese: For some Chinese speaking regions,e.g. China,Taiwan,Hong Kong,we just set Chinese.

2. For most of exporting English speaking regions,e.g. India, Bangladesh, Korea, Brazil, Mexico.

Chinese and English can be exchanged by hand touch on the screen,adjust by workers easily.

Keywords: automatic bobbin winder

Originally published 07 Feb 2023, updated 07 Feb 2023.