02 Dec 2022

The propose of the winding machine is to cooperate with the work of the braiding machine, knitting machine. When the yarn is wound on the bobbin according to the set procedure, after winding process finish, the bobbins will be transferred to the weaving area for use.

After the yarn is wound, the bobbin will have a tail yarn, we call it yarn end, and the existence of the yarn end will affect the efficiency of the braiding work. Before the bobbin is placed on the knitting or braiding machine, the yarn end needs to be cut off, because once the bobbins run on the braiding machine at high speed, the yarn end will run together, you can image, there might be a risk of polluting the yarn. The traditional yarn ends cutting work is done by hand. Manual yarn end cutting is time-consuming, and the yarn may be polluted or damaged when man-made cutting.

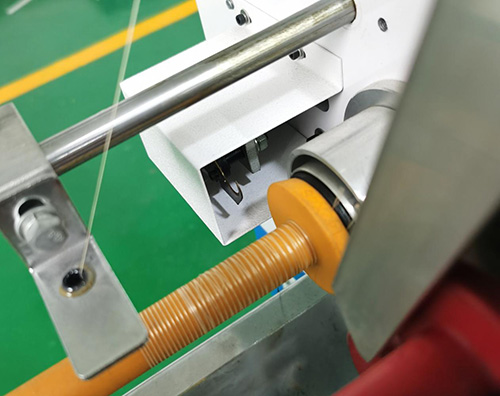

The HRD-826 winding machine solves the problem of yarn end cutting. Unlike ordinary winding machines, HRD-826 has a new automatic yarn end cutting function. The yarn end cutting blade is made of high-quality steel, and the yarn end cutting is smooth and neat. At the beginning of the winding work, the winding machine winds several circles on the bobbin at first, and then cuts the yarn end, and then continue winding. The bobbins winding by the HRD-826 winding machine can be directly used on the braiding machine. Workers do not need to cut the yarn ends, which improves the efficiency of weaving work, reduces labor costs, and reduces yarn loss.

Keywords: winding machine

Originally published 02 Dec 2022, updated 02 Dec 2022.