07 Nov 2025

Operating a yarn winding machine involves four steps: plugging in power, threading yarn, adding bobbins, setting parameters before starting the machine.

Tools

Electricity, Bobbins, yarn

Method

1. Plugging in power

Inserting the power plug and turn on the power switch.

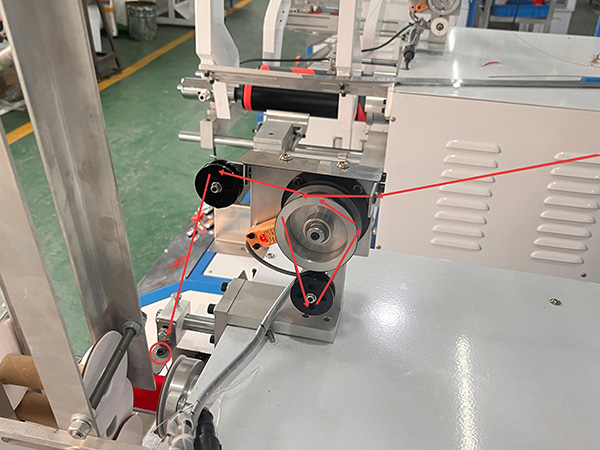

2. Threading yarn

The following pictures show the complete process of threading the yarn in detail. Place the yarn cone that requires winding on the floor. Then pass the yarn through the ceramic eyelet on the creel, the yarn presser and yarn broken device on the creel, and finally guide it through the yarn closer to be wound onto the bobbin.

3. Add bobbins

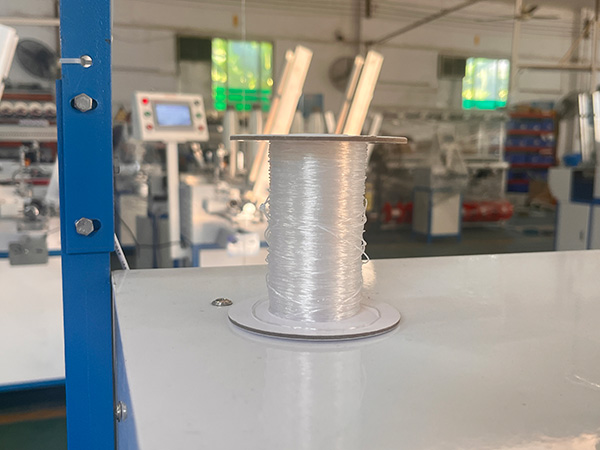

Place the bobbins into the aluminum chute. The wound bobbins will be placed on the feed chutes by automatic unloading equipment when the winding is completed, which effectively prevent contamination yarn collision lax to ensure quality, especially the white and color yarn. HRD-836 has two feed chutes. Therefore,it has a larger capacity for receiving bobbins.

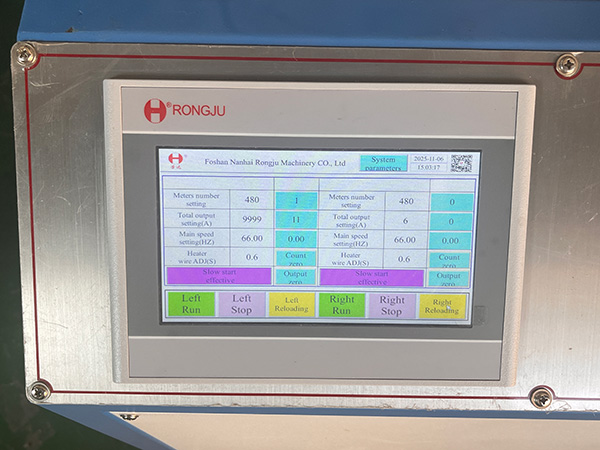

4. Setting parameters and starting the machine

The first step is to set the winding number for the yarn on the control panel of touchscreen.The second step is to press the two green SWITCH. The machine will then start running. The finished product is shown in the following pictures.

Note that if the warning light illuminates, it indicates that the yarn is broken or the photoelectric sensor for blocking material was not installed properly. The machine will automatically stop and can only resume operation once the worker has re-threaded the yarn or reinstall the the photoelectric sensor.

Keywords: Yarn Winding Machine

Originally published 07 Nov 2025, updated 07 Nov 2025.