12 Sep 2025

Operating a rolling machine involves four steps: plugging in power, threading tape, setting parameters and starting the machine.

Tools

Electricity, Air pressure, Tape (Can make webbing with width from 18 to 50mm)

Method

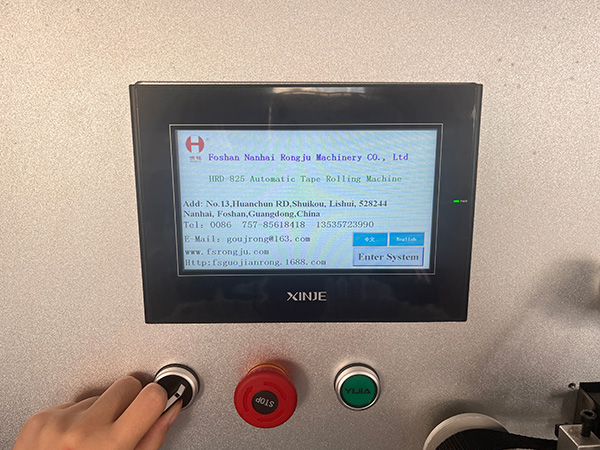

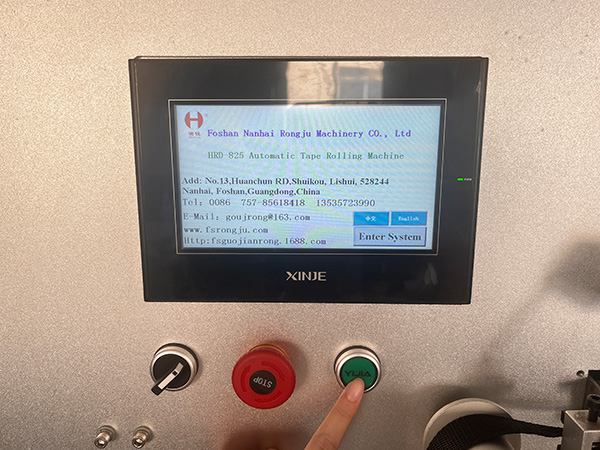

1. Plugging in power

Insert the power plug, then successively press “Machine return to original state” and “Reset”. If not set the machine reset, the machine will not move. Finally turn on the power switch.

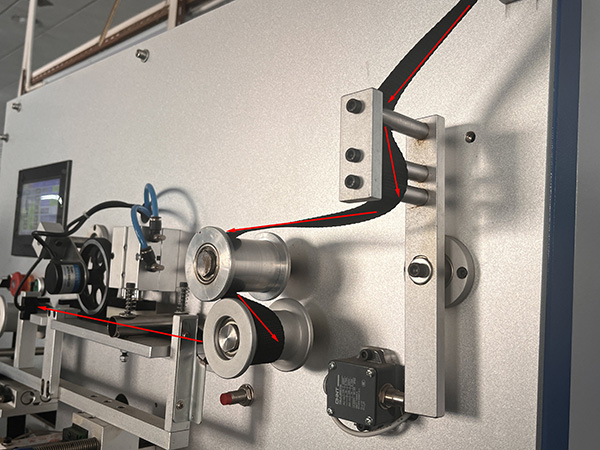

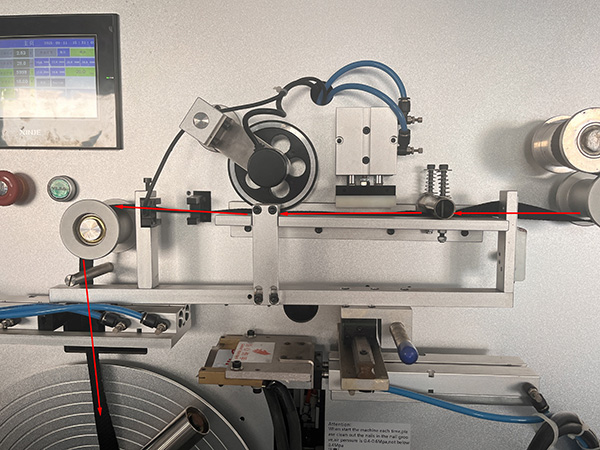

2. Threading tape

The following pictures show the complete process of threading the tape in detail. Place the tape that requires rolling on the box. Then pass the tape through the tape threading device, pressing device and counter sensing device.

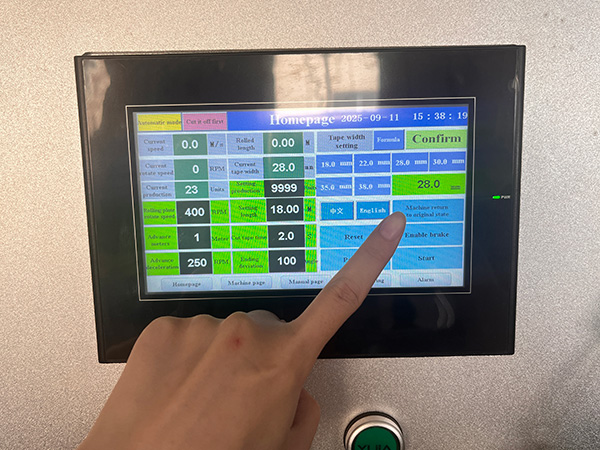

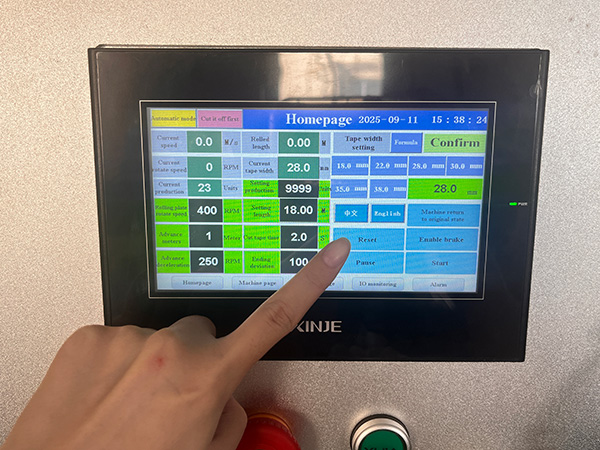

3. Setting parameters and starting the machine

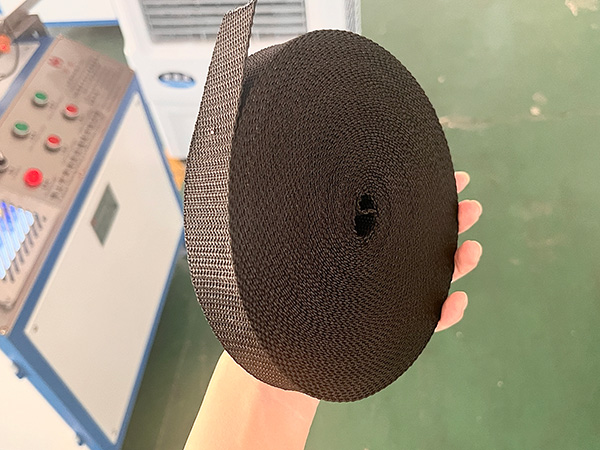

The first step is to set the width of tape, the production and the winding number for the tape on the control panel of touchscreen.The second step is to press the SWITCH. The machine will then start running to roll.The machine will nail the tape after it is wound to fix the finished product to prevent it from falling apart. After nailing, the tape is cut with a heating wire. The finished product is shown in the following pictures.The wound and cut tape will slide down the inclined chute below and you can be ready for a box to receive the finished products.

Note that this machine uses a heating wire to cut the tape. Pls be careful of high temperatures that may hurt your hands.

Keywords: yarn winding machine

Originally published 12 Sep 2025, updated 12 Sep 2025.