05 Sep 2025

Operating a yarn winding machine involves four steps plugging in power, threading yarn, adding bobbins, setting parameters before starting the machine.

Supply

Electricity

Tools

Bobbins, yarn

Method

1. Plugging in power

Inserting the power plug and turn on the power switch.

2. Threading yarn

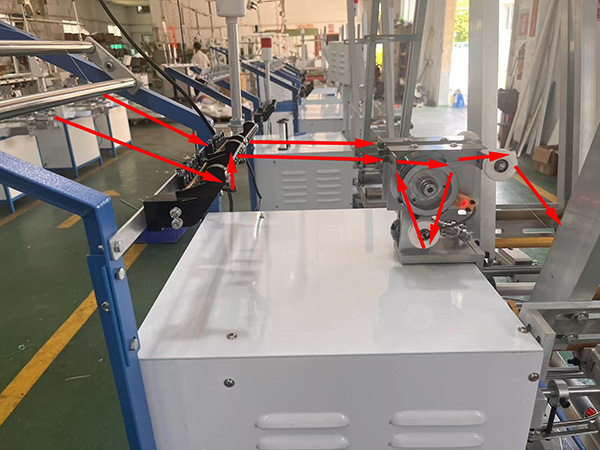

The following pictures show the complete process of threading the yarn in detail. Place the yarn cone that requires winding on the floor. Then pass the yarn through the ceramic eyelet on the creel, the yarn presser and yarn broken device on the creel, and finally guide it through the yarn closer to be wound onto the bobbin.

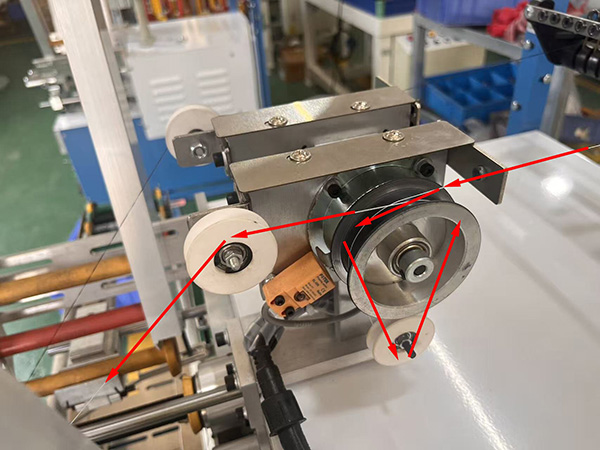

The yarn presser in the picture below is specially designed for different types of yarns, such as fish thread, dyed yarn, slippery yarn, etc. Using a common yarn presser, the above yarn will be very tight when it is wound onto the bobbin, so this special device is needed.

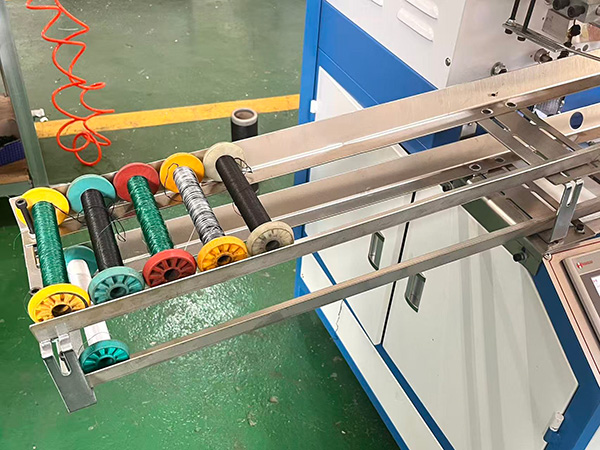

3. Add bobbins

Place the bobbins into the aluminum chute. Each chute can contain 13 bobbins.The wound bobbins will be placed on the feed chutes by automatic unloading equipment when the winding is completed, which efffectively prevent contamination yarn collision lax to ensure quality.HRD-829 has two feed chutes. Therefore, it has a larger capacity for receiving bobbins.Each feed chute maximum can hold 16 bobbins.

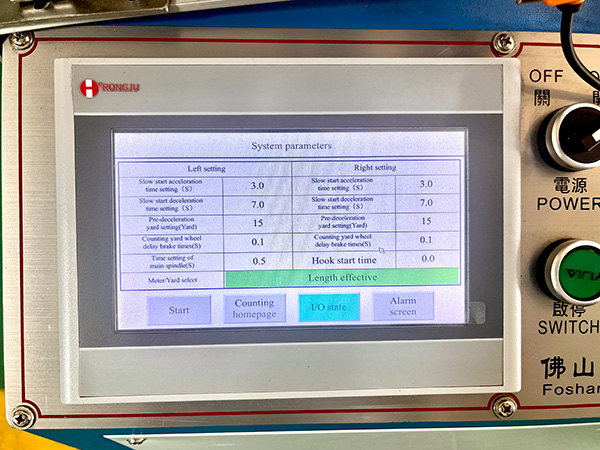

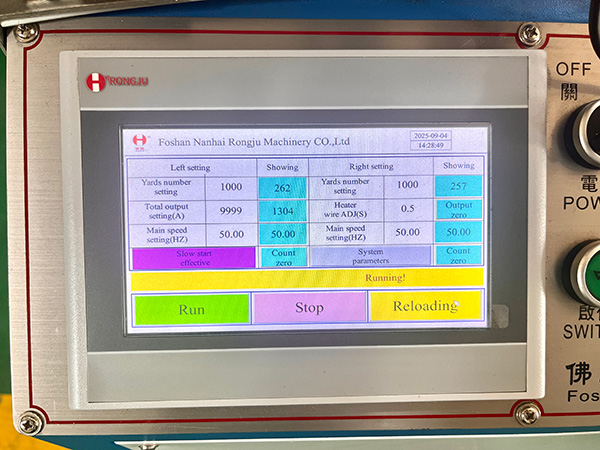

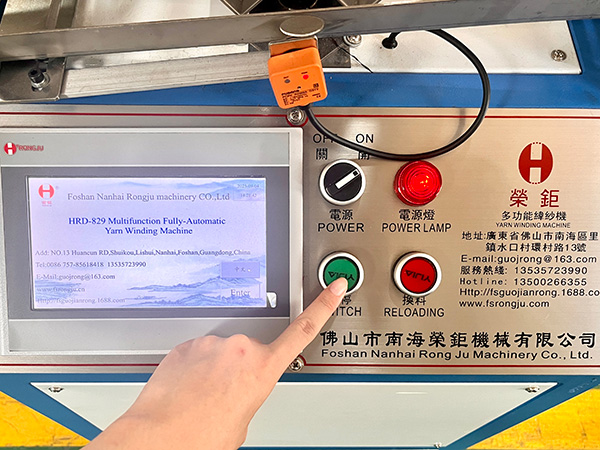

4. Setting parameters and starting the machine

The first step is to set the “Length Effective” and “Optoelectronics valid ” to ensure that photoelectric sensor can sense whether the feed chute is full.The second step is to set the winding number for the yarn on the control panel of touchscreen.The final step is to press the SWITCH. The machine will then start running. The finished product is shown in the following pictures.

The biggest difference between HRD-829 and HRD-819 is that HRD-829 has the yarn counters.The length of winding yarn is uniform,and the yarn can be change at on time on the braiding machine,so the downtime can be reduced,and the output can be increase by 20%-30%,which greatly reduces yarn waste and save labor.In addition, both sides san be individually countded,and dual motors and dual inverters can effectively reduce deviations.

Note that if the warning light illuminates, it indicates that the yarn is broken or the photoelectric sensor for blocking material was not installed properly. The machine will automatically stop and can only resume operation once the worker has re-threaded the yarn or reinstall the the photoelectric sensor.

Keywords: yarn winding machine

Originally published 05 Sep 2025, updated 05 Sep 2025.